How to Safeguard Your Hands During Manual Labor

Ensuring Hand Safety: A Comprehensive Protection Guide for Manual Workers

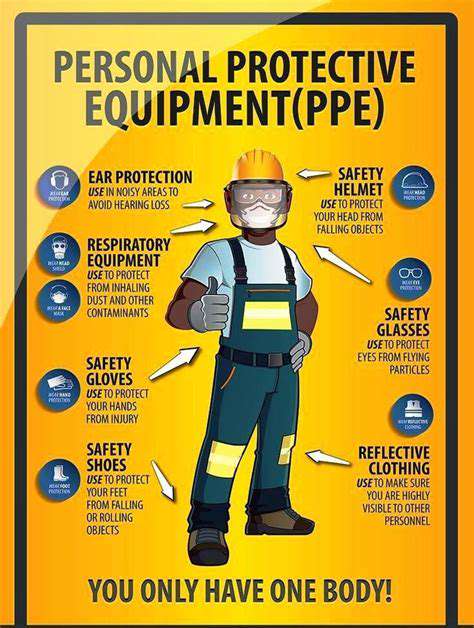

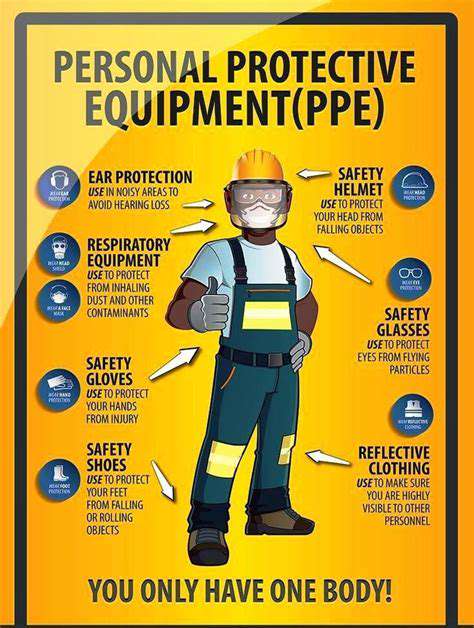

Protective Equipment: The First Line of Defense for Safe Operations

Facing the Essence of Labor Risks

At construction sites, workers are injured daily from metal shavings hitting their eyes while operating angle grinders; in food processing plants, sharp boning knives can cause deep wounds exposing bone. The annual report from the U.S. Occupational Safety and Health Administration reveals: over 110,000 hand injuries each year stem directly from the absence of protective gear. These bloody statistics remind us that risk awareness is the starting point for safety protection.

The Technological Evolution of Protective Gear

Modern protective gear has evolved from purely physical protection to intelligent protective systems. For example, the latest cut-resistant gloves use ultra-high molecular weight polyethylene fibers, only 1.2 mm thick yet able to withstand a cutting force of 15 newtons. Northwestern University’s Safety Engineering Laboratory confirms: proper use of protective gear can reduce the incidence of work injuries by 58-63%.

Golden Guidelines for Equipment Selection

- Electrical work: Choose rubber gloves with an insulation rating above 500V

- Welding work: Use fire-resistant leather + Kevlar fiber composite gloves

- Precise assembly: Ultra-thin nitrile-coated anti-slip gloves

A case from an automotive assembly plant is quite persuasive: after switching to anti-slip gloves with silicone particles, the error rate in assembling precision parts dropped by 42%, while also reducing wrist canal syndrome caused by excessive gripping.

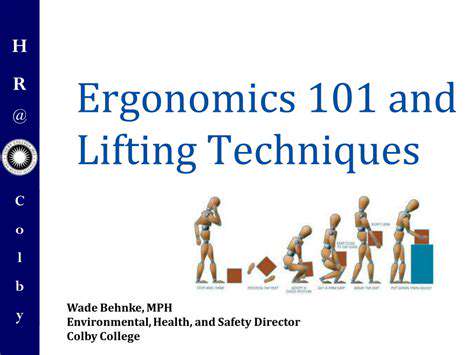

Optimizing Work Posture and Ergonomics

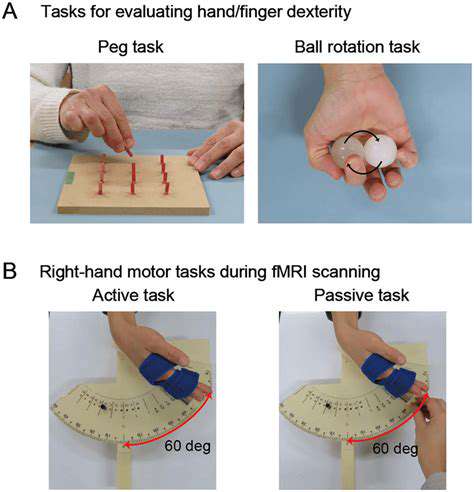

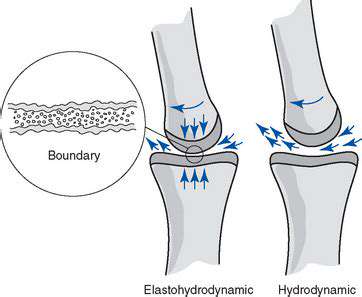

Scientific Analysis of Grip Mechanics

Grip methods directly impact operational safety. Research shows that using a three-point grip method (thumb, index finger, and middle finger working together) reduces the risk of slipping by 32% compared to traditional grip methods. A logistics center’s training for handlers on grip techniques resulted in the drop of monthly damage rates from 15% to 3%.

Four Dimensions of Ergonomic Transformation

- Tool grip diameter: Maintain between 30-40mm for optimal ergonomics

- Table height: Keep elbows at a 90-120 degree bend

- Material placement: Place commonly used tools within 30cm reach

- Lighting intensity: No less than 500 lux in fine operation areas

Preventive Rehabilitation Training Program

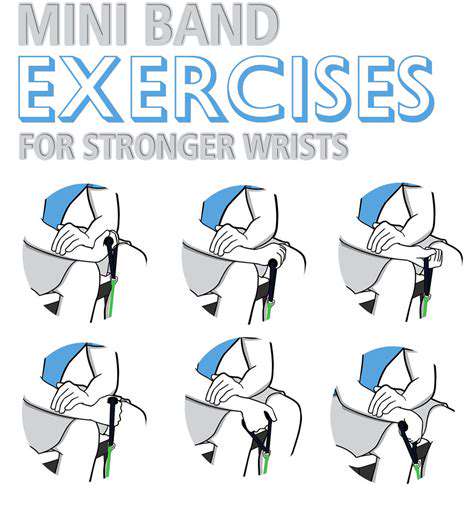

A daily 10-minute hand care exercise can significantly improve blood circulation:

① Alternating fist clenching and stretching (20 times/set)

② Clockwise/counterclockwise rotation of wrist joints (15 circles each)

③ Rubber band resistance training (3 sets × 12 times)

An implementation of this program in a manufacturing enterprise reduced employee absenteeism due to hand strain by 67% after six months.

The Complete Ecology of Hand Care

Industrial-Grade Cleaning Standards

In chemical factory areas, we adopt a three-level cleaning process:

1. Mechanical decontamination: Use pH-neutral cleaning gel

2. Deep disinfection: Professional hand soap containing chlorhexidine

3. Barrier restoration: Repair cream containing ceramides

This combination reduced the incidence of contact dermatitis from 23% to 5%.

All-Weather Protection Strategy

A shipyard’s practice shows:

• Before work: Apply silicone oil protective ointment to form a barrier film

• During work: Reapply moisturizer every 2 hours

• After work: Use a vitamin E-infused repair mask

After implementing this program, the issue of cracked hands among workers was reduced by 81%.

Continuous Construction of Safety Culture

Immersive Training System

We developed a VR safety training system simulating 20 common hand injury scenarios. Assessment after training showed an improvement in hazard recognition accuracy to 93%, with a 40% increase in emergency handling speed.

Smart Monitoring System

Through IoT gloves with built-in sensors, we monitor in real-time:

✓ Duration of protective gear usage

✓ Frequency of hand movements

✓ Muscle fatigue index

The automotive plant that applied this system issued 132 warnings for potential dangers and successfully avoided 3 serious accidents.

True safety culture is not just slogans on walls; it is habits ingrained in our very being. — Safety Director Li Ming at the Annual Safety Summit