Protocols for Arm and Hand Injury Prevention

Identifying Potential Hazards in Your Workplace

Spotting Common Hand and Arm Risks

Recognizing workplace dangers forms the foundation of preventing arm and hand injuries. This requires careful examination of daily tasks, tools used, and the overall work setting. Pay particular attention to repetitive actions, excessive force applications, and unnatural body positions. Grasping how these elements contribute to conditions like carpal tunnel syndrome or tendonitis proves essential when developing protective strategies.

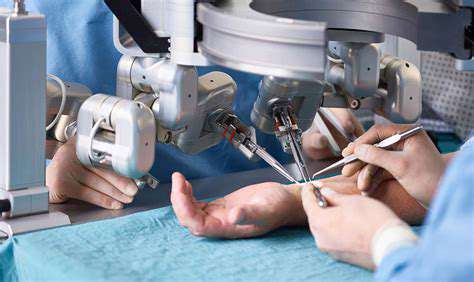

Workplace tools often present hidden dangers. Machinery lacking proper maintenance, tools with sharp edges, or inadequately shielded moving components can all result in serious cuts or worse. Consistent equipment checks combined with strict adherence to safety guidelines serve as primary defenses against such hazards.

Assessing Ergonomics and Workflow

Ergonomic evaluations play a pivotal role in uncovering posture-related risks and repetitive motion issues. Observing employees as they perform tasks helps identify strained positions or awkward movements. This might involve rearranging workstations or adjusting equipment placement to ensure proper body alignment. Applying ergonomic principles effectively can dramatically decrease the likelihood of developing musculoskeletal disorders.

Workflow analysis deserves equal attention. Pinpointing high-stress points or repetitive task sequences allows for process improvements. Solutions might include introducing task rotation, providing ergonomic tools, or redesigning work methods to minimize strain. These adjustments can significantly lower injury risks while maintaining productivity.

Developing Safety Measures and Education

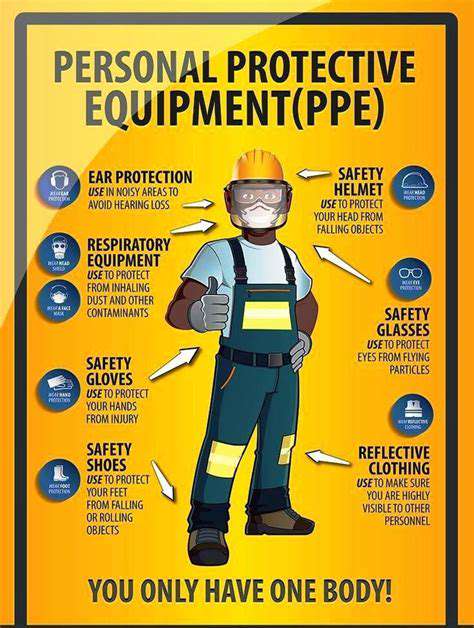

Creating robust safety protocols forms the backbone of injury prevention. This encompasses clear guidelines for handling dangerous materials, proper PPE usage, and comprehensive equipment training. Consistent enforcement of these procedures remains crucial for maintaining workplace safety.

Employee education should extend beyond basic training. Workers need thorough instruction on hazard recognition, proper lifting methods, and safe tool operation. Equally important is establishing clear channels for reporting potential dangers. Regular refresher courses and ongoing safety discussions help maintain awareness and compliance.

Periodic safety evaluations ensure protocols remain effective. These reviews should assess procedure relevance, identify emerging risks, and implement necessary updates. This continuous improvement cycle helps organizations stay ahead of potential safety issues.

Choosing and Caring for Proper Protective Gear

Equipment Selection Essentials

Choosing suitable protective equipment significantly impacts task safety and effectiveness. Thorough evaluation of project requirements, working conditions, and potential risks should guide all selection decisions. This careful consideration ensures chosen gear meets both performance needs and safety standards. Neglecting this process can have serious consequences.

Different protective equipment serves distinct purposes. Understanding these variations ensures proper usage and maximizes protection. Selecting gear specifically designed for the intended application remains paramount for both safety and efficiency. Always prioritize certified equipment that complies with current safety regulations.

Pre-Operation Checks

Conducting detailed inspections before use helps prevent accidents. This involves examining equipment for any damage, excessive wear, or functional issues. These pre-use assessments significantly reduce operational risks and help maintain smooth workflow. Pay special attention to critical components that could fail during use.

Proper preparation extends beyond physical inspection. Users should thoroughly understand operating procedures, safety features, and manufacturer recommendations. Complete operational knowledge forms the foundation for safe equipment use. Never operate equipment without first reviewing all relevant safety information.

Scheduled Maintenance

Regular upkeep preserves equipment reliability and safety. This includes cleaning, lubricating moving parts, and addressing minor repairs promptly. Consistent maintenance dramatically extends equipment lifespan. Following a predetermined maintenance schedule helps prevent unexpected failures.

Always adhere to manufacturer maintenance guidelines. These specifications ensure equipment remains in optimal condition and continues meeting safety standards. Proper lubrication prevents premature wear, while regular cleaning avoids performance-reducing buildup.

Safety Protocol Adherence

Strict compliance with safety procedures protects all personnel. This includes understanding and following all manufacturer instructions and workplace policies. Complete familiarity with safety measures proves essential for accident prevention. Regular verification of safety feature functionality should become routine practice.

Never operate equipment without appropriate personal protective equipment. This includes eye protection, gloves, and other necessary safety gear. Following established safety guidelines minimizes injury risks and promotes responsible equipment use.

Problem Resolution

Effective troubleshooting maintains equipment functionality. Learning to identify and address common issues prevents operational delays and safety hazards. Prompt, appropriate responses to equipment problems minimize downtime and prevent further damage. Consult technical manuals or qualified professionals when needed.

When equipment malfunctions occur, implement temporary solutions if possible while arranging proper repairs. Never continue using potentially unsafe equipment. Prioritizing proper repairs over temporary fixes ensures long-term equipment reliability.

Fostering Workplace Safety Awareness

Building Safety Consciousness

Developing a genuine safety culture requires more than policy implementation. It demands creating an environment where every employee actively participates in safety initiatives. This includes establishing open communication channels for reporting concerns without fear of negative consequences. Regular safety discussions that focus on hazard identification and prevention prove more effective than passive poster campaigns. Leadership must consistently demonstrate safety commitment through both words and actions.

Effective training programs should emphasize critical thinking about safety rather than simple rule memorization. Employees need to understand the real-world consequences of unsafe practices, not just the procedures to follow. This deeper comprehension transforms safety from a requirement to a personal value.

Ongoing Education Programs

Safety training should evolve continuously, not remain static. Programs must address current workplace hazards with particular attention to arm and hand injury prevention. Interactive training methods like hands-on demonstrations significantly improve knowledge retention. Ensure training materials remain current with industry standards and technological advancements.

Practical Safety Implementation

Theoretical knowledge only becomes valuable when applied. Training should incorporate realistic scenarios that allow employees to practice safety protocols. Encouraging worker participation in hazard identification and solution development fosters ownership of safety. Regular evaluations of training effectiveness help identify areas needing improvement.

Protocol Enforcement and Review

Clear enforcement mechanisms ensure consistent safety protocol adherence. This includes defined consequences for non-compliance alongside recognition for safety-conscious behavior. Routine workplace inspections help identify both hazards and protocol violations. Establish feedback systems that allow employees to suggest safety improvements, ensuring protocols remain relevant and effective over time.