How to Develop a Preventive Plan for Hand Injuries

Identifying Potential Hazards in Your Work Environment

Understanding Common Workplace Hazards

Spotting potential dangers in your workplace forms the foundation of any robust safety strategy. This process requires keen observation of both visible threats like heavy equipment and subtle risks such as repetitive motion injuries. Every work environment presents unique challenges, making tailored hazard recognition essential for effective prevention.

Conducting a detailed evaluation involves examining work processes, tool usage, physical space organization, and operational workflows. This systematic approach dramatically lowers accident probabilities while enhancing overall workplace efficiency and employee well-being.

Evaluating Equipment and Machinery Safety

Well-maintained equipment serves as the backbone of operational safety. Implementing rigorous inspection routines for all machinery helps identify potential issues before they escalate. Look for warning signs like unstable components, damaged electrical wiring, or unusual operational noises that might indicate developing problems. Adherence to manufacturer guidelines during equipment operation remains non-negotiable for maintaining safe working conditions.

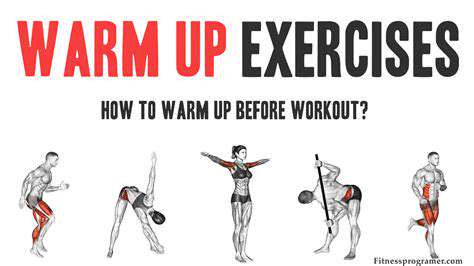

Assessing Ergonomics and Posture

Workstation design significantly impacts employee health over time. Improper seating arrangements, repetitive tasks without variation, and constrained body positions frequently contribute to chronic pain conditions. Thoughtful evaluation of workspace configuration - including monitor placement, keyboard positioning, and seating ergonomics - can prevent numerous musculoskeletal complaints.

Investing in proper training about body mechanics and posture fundamentals pays long-term dividends in workforce health and productivity.

Analyzing Chemical and Biological Hazards

Many workplaces contain substances requiring special handling protocols. Comprehensive knowledge about material properties, proper storage requirements, and emergency procedures forms the critical first line of defense against chemical exposures. Maintaining current safety data sheets and conducting regular training sessions ensures all personnel understand proper handling techniques for hazardous materials.

Evaluating Environmental Factors

Ambient conditions frequently influence workplace safety more than many realize. Insufficient lighting creates trip hazards, temperature extremes affect concentration and physical comfort, while poor air circulation may lead to respiratory concerns. Periodic assessment of these environmental elements helps maintain optimal working conditions that support both safety and productivity.

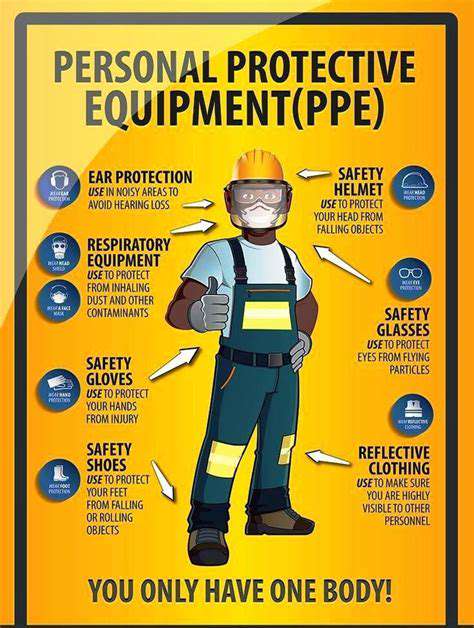

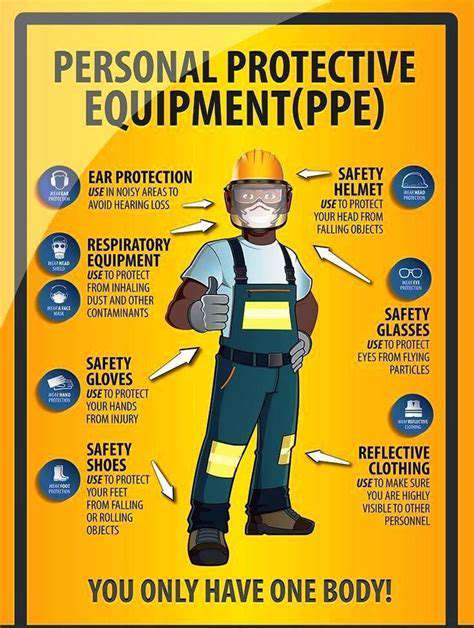

Implementing Control Measures and Procedures

Effective hazard management requires a multi-layered approach. Physical safeguards like machine guards combine with procedural controls such as safety training programs and appropriate personal protective equipment usage. This comprehensive strategy creates overlapping protective layers that significantly reduce workplace injury risks while maintaining operational efficiency.

Monitoring and Evaluating the Effectiveness of the Plan

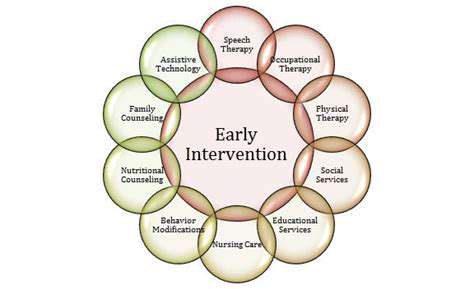

Monitoring the Effectiveness of Interventions

Tracking intervention outcomes provides crucial insights into program effectiveness. Systematic observation of performance metrics reveals patterns that might otherwise go unnoticed, allowing for timely adjustments. Establishing clear benchmarks at the outset creates measurable standards against which to assess progress.

Successful monitoring depends on stakeholder collaboration to ensure selected indicators truly reflect program objectives and organizational priorities.

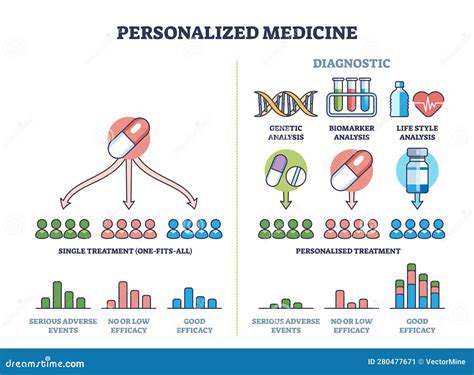

Evaluating the Impact on Target Populations

Effective program assessment considers the diverse characteristics of participant groups. Cultural background, economic circumstances, and existing health conditions all influence how individuals experience and benefit from interventions. Combining numerical data with personal narratives creates a complete picture of program effectiveness.

Gathering qualitative feedback through interviews and discussion groups reveals participant perspectives that quantitative measures might miss.

Identifying Key Performance Indicators (KPIs)

Well-chosen metrics form the foundation of meaningful evaluation. KPIs should directly connect to program goals while remaining practical to measure consistently. For educational initiatives, relevant indicators might include participation rates, skill demonstration outcomes, and longitudinal performance trends.

Addressing Challenges in Data Collection

Obtaining reliable information presents numerous practical difficulties. Developing standardized collection protocols, training data gatherers thoroughly, and establishing quality control measures all contribute to data integrity. Anticipating potential gaps and establishing contingency plans helps maintain evaluation continuity.

Analyzing Data and Reporting Findings

Thorough examination moves beyond surface-level statistics to uncover meaningful patterns. Advanced analytical techniques can reveal relationships between variables that inform future program adjustments. Presenting findings in clear, actionable formats ensures stakeholders can readily understand and utilize the information.

Disseminating Findings and Implementing Adjustments

Sharing evaluation results completes the improvement cycle. Transparent communication with all invested parties builds trust and facilitates collaborative refinement of interventions. Implementing evidence-based modifications creates continuous quality enhancement in workplace safety programs.

This cyclical process of assessment and adjustment ultimately leads to progressively more effective safety initiatives over time.