Revolutionary Strategies for Preventing Finger Injuries

Ergonomics and Workplace Safety for Hand Protection

Importance of Ergonomic Design for Hand Protection

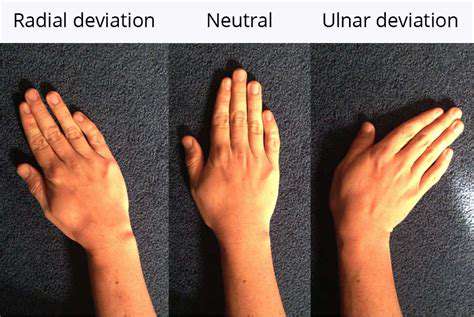

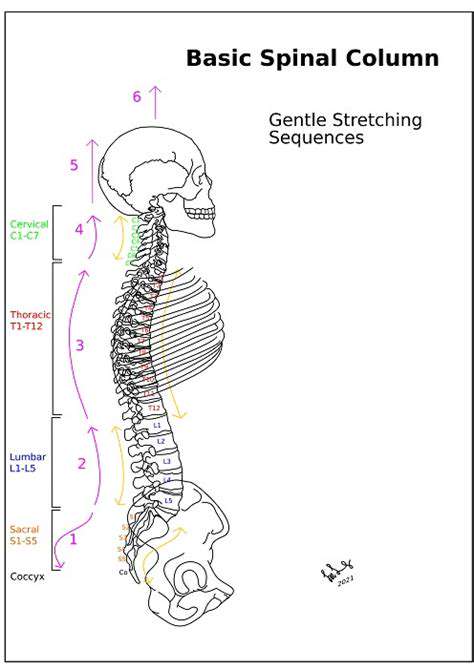

Ergonomic design plays a crucial role in preventing hand injuries in the workplace. Properly designed tools, equipment, and workspaces can significantly reduce the strain and stress on workers' hands, minimizing the risk of repetitive strain injuries (RSI), cuts, punctures, and other occupational hazards. By considering the physical demands of the task and the limitations of the human body, ergonomic design ensures that hand protection measures are integrated effectively into the workflow, ultimately creating a safer and more productive work environment. This proactive approach is essential for maintaining worker well-being and preventing costly downtime associated with injuries.

Effective ergonomic design considers the specific movements and postures required for each task. This includes factors like the reach distance, grip strength needed, and the duration of the work. Careful consideration of these factors allows for the design of tools and equipment that are comfortable and efficient to use. This, in turn, reduces the risk of fatigue and discomfort, which are major contributors to workplace accidents. By prioritising ergonomic principles, employers can cultivate a safer and more productive work culture.

Selecting Appropriate Hand Protection Equipment

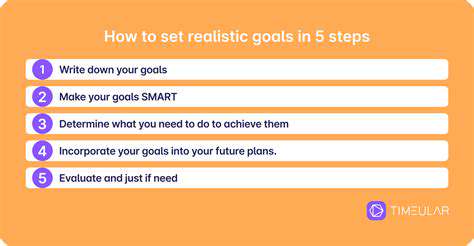

Choosing the right hand protection equipment is paramount for safeguarding workers. Different tasks require different levels of protection, and the selection should be based on the specific hazards present. For instance, tasks involving sharp objects necessitate gloves with puncture resistance, while those involving chemicals require gloves with specific chemical resistance. A comprehensive risk assessment is essential to determine the appropriate level of protection needed for each task, ensuring that workers are not exposed to unnecessary risks.

Understanding the specific materials and properties of various hand protection equipment is vital. Consider factors like dexterity, comfort, and durability when making your choice. Gloves made from durable materials like leather or coated fabrics can provide superior protection against abrasion and cuts, while lighter-weight materials may be better suited for tasks requiring greater dexterity. Thorough research and proper training on the use of chosen equipment are critical for ensuring effective protection.

Implementing Effective Handwashing Protocols

Maintaining meticulous hand hygiene is a cornerstone of workplace safety, particularly for hand protection. Implementing effective handwashing protocols is essential for preventing the spread of infections and reducing the risk of contamination. Providing readily available and easily accessible handwashing stations with soap and running water is crucial. Clear signage and instructions on proper handwashing procedures should be prominently displayed in the workplace, ensuring that all employees are aware of and follow these protocols diligently.

Regular reminders and training sessions on hand hygiene can significantly improve compliance. Encouraging frequent handwashing, particularly after handling potentially hazardous materials or before breaks, reinforces the importance of this practice. These measures contribute to a cleaner and healthier work environment, reducing the likelihood of infections and promoting overall well-being.

Training and Education for Hand Protection

Comprehensive training and education programs are vital for ensuring that workers understand the importance of hand protection and how to use it correctly. These programs should cover the various types of hand protection equipment available, the specific hazards associated with different tasks, and the proper procedures for donning, using, and removing hand protection equipment. Detailed instructions on the limitations and potential risks of each product should be included.

Regular Safety Inspections and Audits

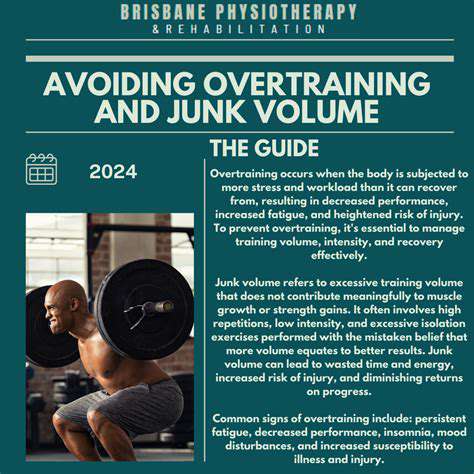

Implementing regular safety inspections and audits is a crucial aspect of maintaining a safe workplace environment. These inspections should focus on the condition and usage of hand protection equipment to identify any potential hazards or deficiencies. Regular assessments ensure that hand protection equipment remains in optimal working condition and that workers are using it correctly. These inspections can also identify gaps in existing safety protocols and suggest improvements to enhance the effectiveness of hand protection measures.

Maintaining a Culture of Safety and Awareness

Establishing a proactive safety culture is essential to fostering hand protection awareness and best practices. Regular communication and reminders about hand protection procedures can reinforce the importance of safety. Encouraging workers to report any hazards or concerns promptly is crucial. Creating a culture where safety is prioritized and mistakes are addressed constructively can significantly reduce the risk of hand injuries. Open communication and collaboration between management and employees are key elements in building this proactive safety culture.