Trendsetting Tips for Preventing Wrist Injuries

Identifying High-Risk Activities and Ergonomics

Understanding High-Risk Activities

Identifying and categorizing activities that place individuals at a higher risk of developing work-related musculoskeletal disorders (WMSDs) is crucial for effective prevention strategies. These high-risk activities often involve repetitive motions, awkward postures, forceful exertions, vibration, or prolonged static postures. Understanding the specific demands of each activity allows for tailored interventions and the implementation of preventative measures to mitigate potential harm.

Analyzing the frequency, duration, and intensity of these activities is key to assessing the cumulative risk. A thorough understanding of the task's physical demands, combined with an evaluation of individual factors like pre-existing conditions and physical capabilities, is essential for a comprehensive risk assessment.

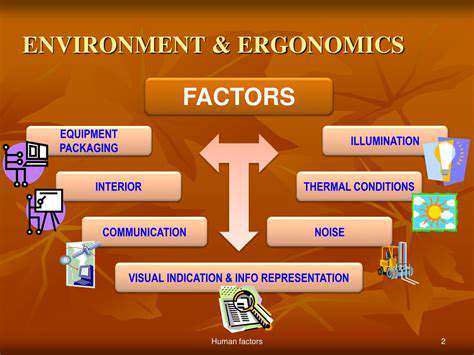

Ergonomic Considerations in Posture and Movement

Maintaining proper posture throughout various work tasks is paramount in preventing musculoskeletal injuries. This includes maintaining a neutral spine alignment, avoiding prolonged bending, twisting, or reaching, and ensuring proper body mechanics during lifting and carrying. Ergonomic principles should be applied to the design of workstations and tools to support natural body alignment and minimize strain.

Effective ergonomic design considers the individual's physical characteristics and capabilities. Adjusting chair height, desk height, and monitor placement to match the user's anthropometrics significantly reduces the risk of developing musculoskeletal problems. Regularly evaluating and modifying workstations to accommodate changes in tasks or individual needs is crucial for maintaining a safe and healthy work environment.

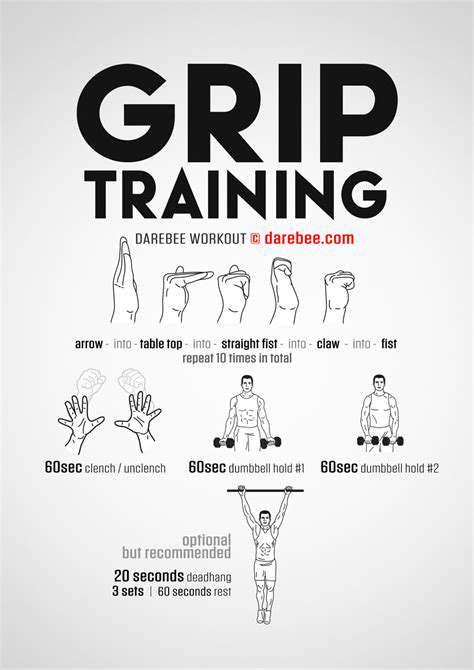

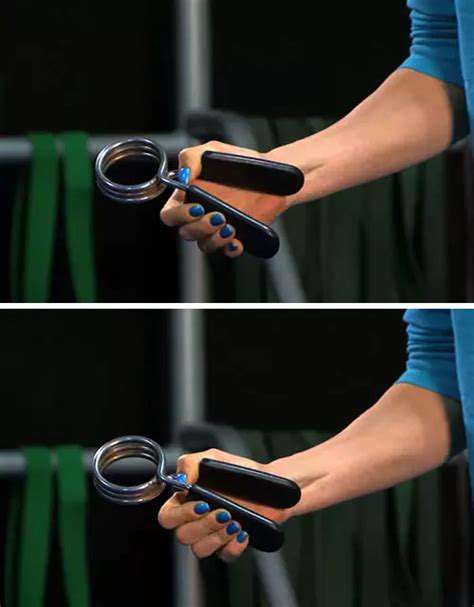

Impact of Repetitive Motions on the Body

Repetitive motions, often performed over extended periods, can lead to significant strain on muscles, tendons, and ligaments. Understanding the repetitive nature of a task and the potential for cumulative trauma is crucial. Implementing strategies to reduce the frequency and duration of repetitive movements, such as job rotation, task variation, and tool adjustments, can help alleviate the strain on the body.

Monitoring the worker's physical response to repetitive motions is essential. Recognizing early signs of discomfort or pain, and taking prompt action to address these symptoms, can prevent more severe injuries from developing.

Forceful Exertion and Lifting Techniques

Activities involving forceful exertions, such as lifting heavy objects, pushing, or pulling, pose a significant risk of musculoskeletal injuries. Proper lifting techniques, including maintaining a wide base of support, keeping the back straight, and engaging core muscles, are crucial for reducing the strain on the spine and other musculoskeletal structures. Using assistive devices, such as lifting equipment or mechanical aids, can significantly reduce the force required and minimize the risk of injury.

Importance of Workstation Design

The design of the workstation plays a critical role in preventing injuries. Ergonomically designed workstations should consider factors such as appropriate chair height, desk height, monitor placement, and keyboard and mouse positioning. Maintaining proper spacing and accessibility for all necessary tools and materials is crucial for reducing strain and promoting efficient movement.

The placement of equipment and materials should consider the worker's reach and movement patterns to minimize unnecessary strain and promote a natural posture. Providing adjustable components allows for customization to accommodate individual needs and preferences, further reducing the risk of injury.

Prolonged Static Postures and Rest Breaks

Prolonged periods of maintaining a static posture, such as sitting for extended periods, can lead to muscle fatigue and stiffness. Regular breaks and movement throughout the workday are essential to alleviate these issues. Implementing scheduled rest periods allows the body to recover and prevents the buildup of tension and discomfort. Encouraging movement during breaks, such as stretching or walking, can further enhance recovery and reduce the risk of developing musculoskeletal problems.

Individual Factors and Risk Assessment

Individual factors, such as pre-existing conditions, physical capabilities, and body mechanics, significantly influence an individual's susceptibility to musculoskeletal disorders. A comprehensive risk assessment should consider these individual factors. Workers with pre-existing conditions or injuries should be assessed for specific risks and provided with tailored ergonomic solutions. Promoting awareness of proper body mechanics and providing training to individuals can significantly reduce risk factors.

Choosing the Right Tools and Equipment for Your Tasks

Selecting Essential Tools

Choosing the right tools is crucial for any project, ensuring efficiency and quality. A well-equipped toolbox allows you to tackle tasks with precision and confidence. Investing in high-quality tools is an investment in your project's success, as they often last longer and perform better than cheaper alternatives. This is especially true for tasks that require repetitive movements or significant force.

Consider the specific tasks you'll be performing. Different tools are designed for different purposes, and using the wrong tool can lead to wasted time and effort. For instance, a delicate carving project requires different tools than a robust construction project.

Understanding Equipment Functionality

Proper understanding of equipment functionality is paramount to its effective use. Understanding how each tool works, its capabilities, and its limitations is essential for achieving the desired outcome. This knowledge empowers you to maximize the tool's potential and avoid potential hazards. This includes knowing safety procedures and recognizing potential risks.

Detailed manuals and online resources can significantly aid in understanding the equipment's operation. Familiarize yourself with the tool's parts, their functions, and potential misuse scenarios. Practicing with the equipment in a controlled environment before using it in a live setting can significantly enhance your understanding and confidence.

Prioritizing Safety Measures

Safety should always be a top priority when working with any tools or equipment. Proper safety gear, such as protective eyewear, gloves, and appropriate footwear, can significantly reduce the risk of injuries. Ensuring that the work area is well-organized and free from obstructions can also prevent accidents.

Regular maintenance of tools and equipment is another critical safety measure. This includes checking for any damage or wear and tear, lubricating moving parts, and ensuring that everything is functioning as intended. Following manufacturer guidelines and safety protocols will significantly decrease the probability of accidents.

Evaluating Budget and Availability

Budgetary constraints and equipment availability often play a significant role in selecting the right tools and equipment. Assessing the project's budget is essential to determine which tools and equipment can be afforded. Finding affordable yet reliable options is often key to success.

Checking the availability of tools and equipment in your local area or online can also influence your decision-making. This includes understanding potential delays in shipping or delivery of specific equipment. Planning ahead and considering these factors will help to avoid any potential disruptions to your project timeline. Furthermore, consider renting equipment if necessary to avoid unnecessary expenditures.